Liquid Billet Lubrication

3063 & 46 ILX EJECTEZE

Lubrication for Shear

3049 & BL 463 2S EJECTEZE

Electrostatic Powder Billet Lubrication

3500 & 410 BNP DYLUBE

Manual Billet Release & Anti-Seize

325 LX EJECTEZE

Saw Lubrication

6000E & CANMIST

Lubrication Technologies for Aluminum Extrusion and Casting

Why Boron Nitride Powder for Billet Lubrication?

Exceptional Release Properties

Boron Nitride does an outstanding job of preventing aluminum build up on the dummy block, expansion ring, and mandrel.

Increase Safety and Productivity

Eliminating manual lubrication will increase uptime while also keeping employees safe around hot moving equipment.

No Mixing Required

Other billet lubrication methods often require water dilution which may not be suitable for every operation.

Features and Benefits of Electrostatic Powder Billet Lubrication

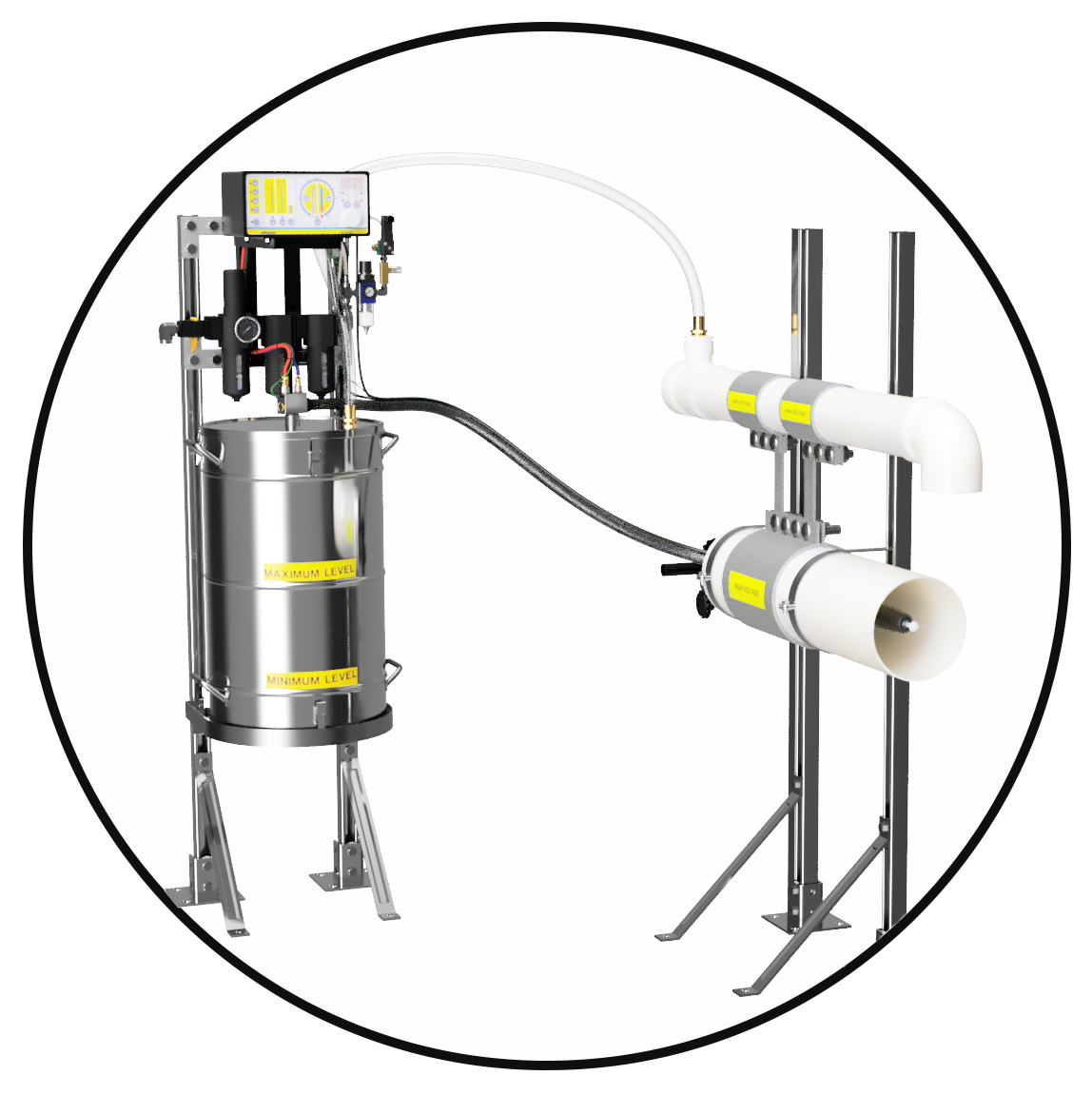

3500 Series

Electrostatic Powder Application System

410 BNP EJECTEZE

Boron Nitride Powder

Designed for Aluminum Billet Extrusion

- Protected Powder Gun

- Pre-Set Controller is Easily Integrated

with Press PLC - Custom Volume Output Control

Sealed Fluidizing Bed Hopper

- Fluidizing Air Mixes and Dries Powder

- Stainless Steel

- Reduce Exposure to moisture

Dust Collection Hood

- Plumbs to Vibra-shake Vacuum

- Removes Excess Over-Spray

- Eliminate Mess

- Dust Collection Hood

410 BNP EJECTEZE

Boron Nitride Powder

Formulated for Aluminum Extrusion

- Provides Electrostatic Properties for Effective

Transfer to Billet - Does Not Affect Finished Material

- Excellent Adhesion to Aluminum

Provides Superior Release

- Combats Aluminum Build-up

- Migrates to Hard to Reach Areas on Tooling

- Requires Minute Quantity

Use As-Is

- Proprietary Boron Nitride Blend

- One Full Pail Fits Perfectly in 3500 Hopper

- Comes Sealed to Avoid Moisture Contamination

Proven Technology, Refined Over Decades