Liquid Billet Lubrication

3063 & 46 ILX EJECTEZE

Lubrication for Shear

3049 & BL 463 2S EJECTEZE

Electrostatic Powder Billet Lubrication

3500 & 410 BNP DYLUBE

Manual Billet Release & Anti-Seize

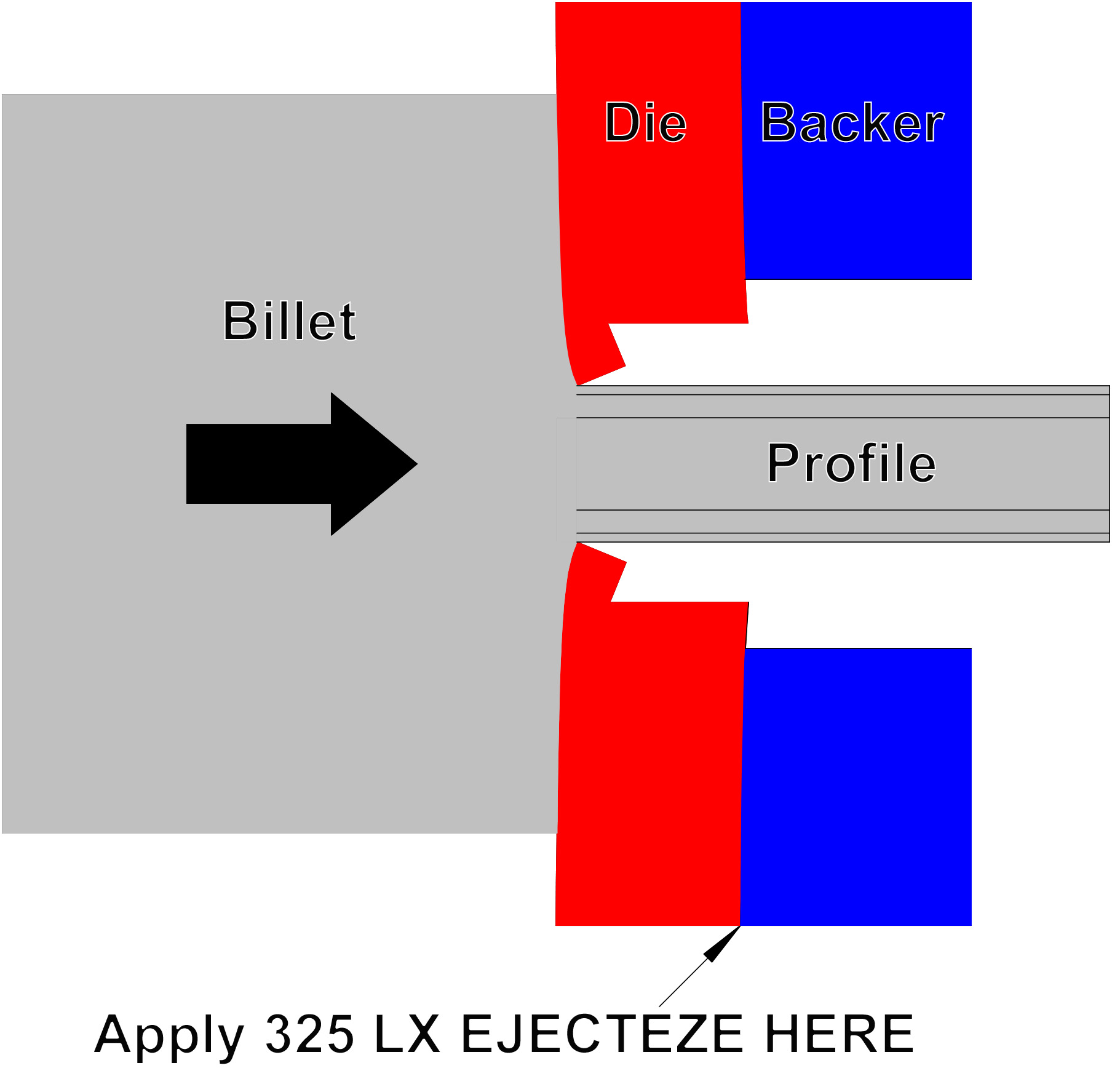

325 LX EJECTEZE

Saw Lubrication

6000E & CANMIST

Eliminate Snap Lines and Ease Breakthrough in Aluminum Extrusion

Snap Lines, also called snap marks or deflection lines, are lines that appear on the surface of an aluminum extrusion during the extrusion process. These thin lines appear perpendicular to the extrusion direction around the entire extrusion.

Snap Lines occur when the die makes sudden, small movements while under pressure. These movements are caused when the die deflects through the backer from pressure and friction in the extrusion process. The strength of the steel die is compromised by the profile opening; the larger the profile, the more the die can deflect. Eventually, the die moves in the stack to relieve the pressure and this creates a snap line.

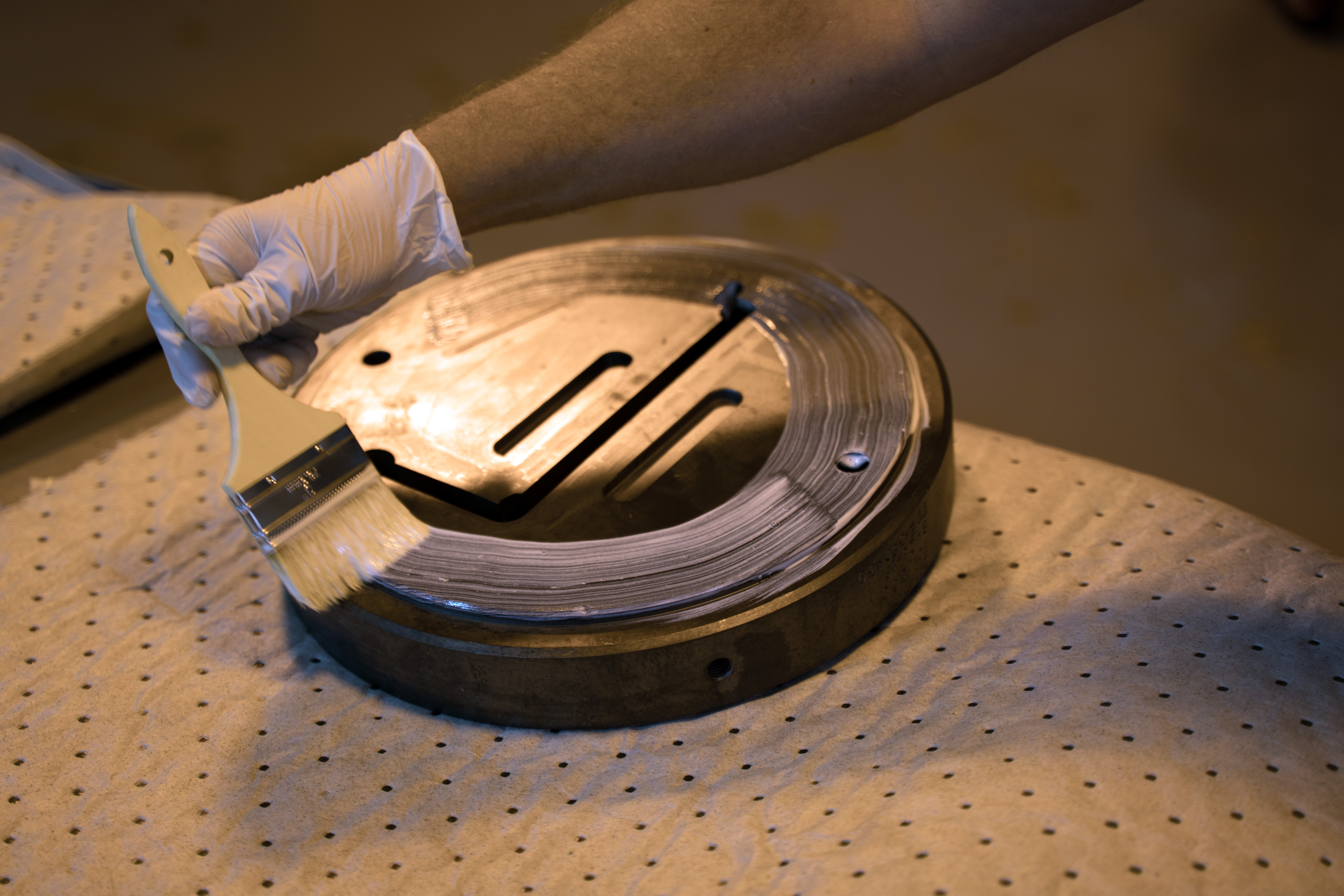

325 LX EJECTEZE helps to eliminate snap lines. Apply a thin coating to the mating surfaces of the die stack with a brush prior to preheating. 325 LX EJECTEZE is a high-temperature, high-pressure lubricant that dries to a thin film in the die oven.

When the tooling is assembled in the stack and put in the press, this thin lubricant film allows the pieces of the tooling to move against each other more freely… even under pressure. As the die deflects under pressure the die and backer plate move so that stress is not built and released under pressure.

325 LX EJECTEZE also acts as anti-solder to aid breakthrough.

When applied carefully to the die port, 325 LX EJECTEZE can also help prevent soldering and build-up of aluminum in the die during the breakthrough.

The end results are mark-free extrusions and reduced defects.

Proven Technology, Refined Over Decades.